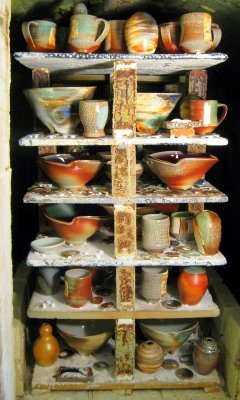

A Happy Soda Firing

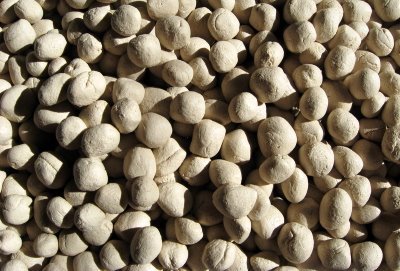

Wadding Recipe for the soda kiln (pretty standard) (by volume):

- 1 part EPK

- 1 part alumina hydrate

- medium grog to taste (not really, but you know what I mean...)

I roll my wads ahead of time and put them in a plastic container (the ones from the local Thai take-out place are the best). Then I glue them to the bottoms of pots before loading (Elmer's glue). Breaking up the wadding into steps keeps my hands cleaner and helps me avoid the problem of getting wadding where it doesn't belong.

(new) Soda Mixture:

Mixed together with 1/4 of a 5 gallon bucket of wood chips. Mix together well, then add enough water (while mixing) to the consistency of oatmeal cookie dough. I add it on an piece of angle iron through the ports on the front of the kiln when c. 9 is soft. (More on this in a future post.)

- 1.75 lbs. of soda ash

- 2.25 lbs. of soda bicarb

- 4 lbs. of whiting

Mixed together with 1/4 of a 5 gallon bucket of wood chips. Mix together well, then add enough water (while mixing) to the consistency of oatmeal cookie dough. I add it on an piece of angle iron through the ports on the front of the kiln when c. 9 is soft. (More on this in a future post.)

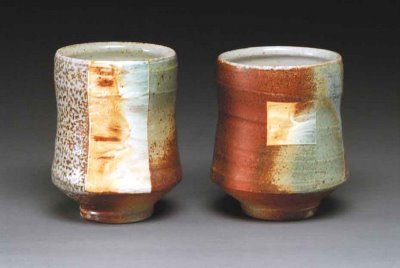

Below are some tea bowls that I got out of this firing.